Denver Water brings energy savings into the light

Denver Water has seen the light — and it’s brighter, cheaper, saves gobs of energy and cuts greenhouse gas emissions.

As part of its sweeping push for sustainable practices, the utility is roughly halfway through a years-long lighting retrofit. It’s moving from traditional lighting systems that use metal halides and fluorescents to LEDs that last 10 times longer, use far less electricity and cut maintenance costs.

And the switch isn't just taking place in its business offices.

Denver Water electrical workers are retrofitting lights at pump stations, treatment plants — even hydropower facilities.

“It’s been a massive undertaking, but we’re making a dent,” said Ralph Cocozzella, electrical shop supervisor at Denver Water.

A few examples:

- At the Recycling Plant, workers replaced exterior and interior lights. The switch will save nearly $5,000 a year and nearly 79,000 kilowatt-hours of power. For context, one kilowatt-hour is about what a medium-sized window air conditioning unit requires to run for one hour; or about what two desktop computers running for a workday consume.

- Last fall, a lighting retrofit at Dillon Reservoir’s hydroelectric plant resulted in a savings of $2,125 and more than 35,000 kilowatt-hours of electricity a year. That translates to a reduction in greenhouse gas emissions of 28 tons per year.

- A massive retrofit at Marston Treatment Plant in southwest Denver completed in 2017 replaced exterior lights and part of the plant's interior lighting, saving more than $10,000 and nearly 205,000 kilowatt-hours of power a year. It also reduces carbon dioxide emissions by a whopping 161 tons per year.

- At three pump stations this year, interior lighting replacements are projected to save nearly $3,000 and 40,000 kilowatt-hours annually.

Not only has the change in lighting reduced costs and environmental impacts, but the lighting itself is far better. In fact, the need for better lighting quality was part of what triggered change.

“It started out with operators calling in and saying, ‘Can we get better lighting?’ Because the old metal halides on the wall — it’s kind of hazy and dark,” said Tom Hoefler, electrical shop lead. “The LEDs light things up so people have better conditions to see what they’re doing.”

The retrofits do come with a significant upfront expense. Lights that use LEDs, short for light-emitting diodes, are costlier and some of the installation work requires rewiring.

But those costs are recovered — and then some — by drops in electricity usage, the durability of the lights and the associated drop in maintenance.

Further, Xcel Energy Inc. has provided rebates as additional incentive in making the investments. The rebates ease the impact of acquiring the new lights and shortens the payback time.

Through the rebates, Denver Water has recouped 18% to 38% of the upfront costs depending on the project. In the case of the retrofit at the Moffat Treatment Plant in 2018, payback was reduced from eight years to less than 2½ years because of nearly $3,000 in rebates.

“This is pretty typical for how rebates reduce the payback period,” said Adam Hutchinson, energy management specialist for Denver Water. “It’s something I try to highlight for our facility operators. I can’t recall a payback period longer than four years after rebates are factored in.”

And it’s not only the lights themselves that are part of Denver Water’s push for sustainable operations. The utility is increasingly using light timers, motion detectors and other methods to ensure lights are only in use when necessary.

“Everything, as far as the lighting, has to do with sustainability,” Cocozzella said. “Denver Water has been so proactive in any new facilities they are building. It also pushes to retrofit existing buildings to cut the cost of lighting.”

And sustainability efforts don't end when the lights are switched.

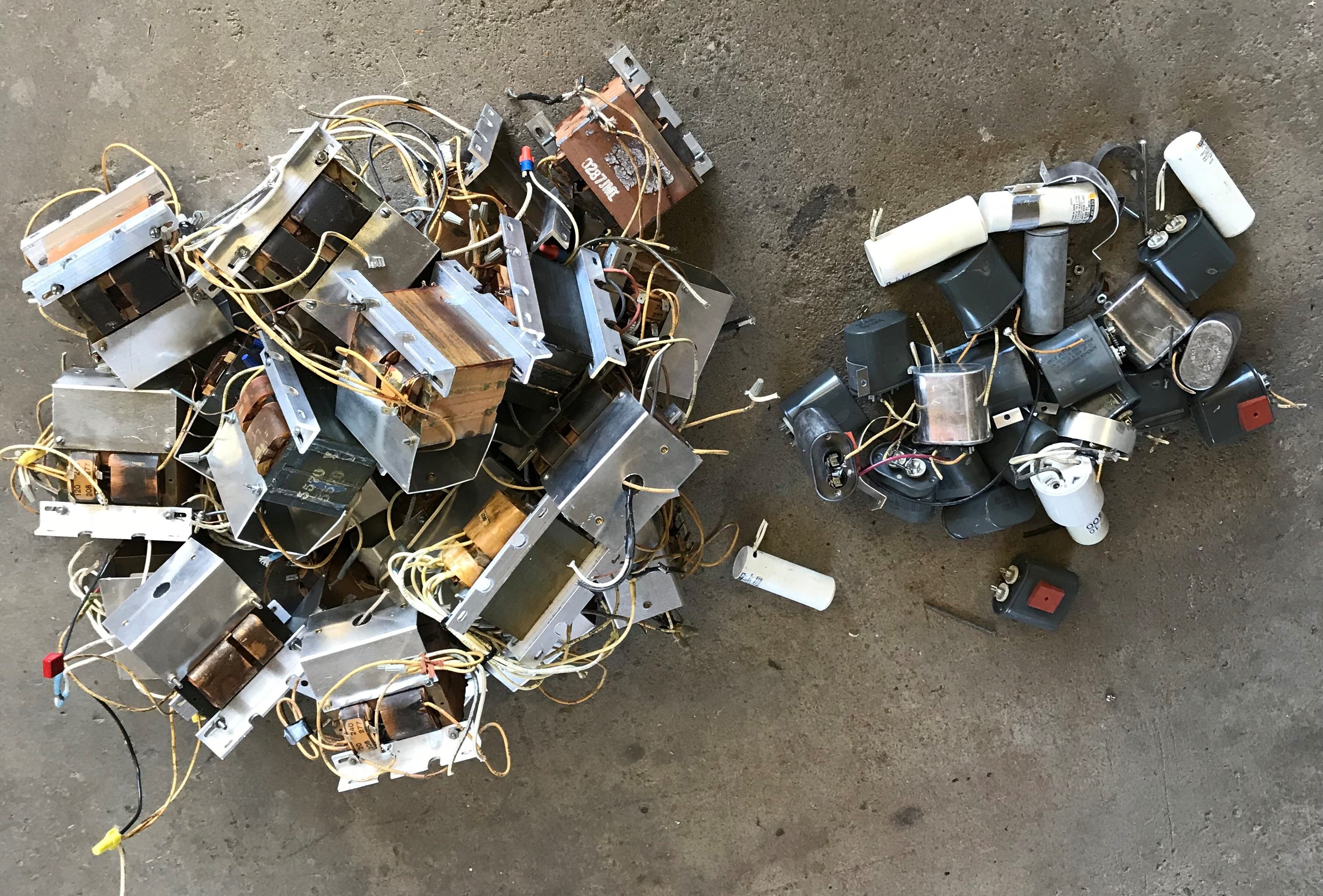

After the old lights are removed, the electrical shop staff has worked with Denver Water’s environmental unit to separate the scrap into steel, plastic, glass and other components so the materials can be recycled.

“We’re trying to do this right all the way around,” Cocozzella said. “Save customer money, save energy and conserve resources.”

Read more about Denver Water’s ongoing sustainability initiatives in stories on recycling and reducing landfill waste, e-waste recycling, how the utility is addressing climate change, its long history of green practices, the sustainable elements of its evolving operations complex and its development of utility-wide sustainability goals.

These and other related stories are available on TAP.