Getting some ‘concrete’ answers about the Gross Reservoir Expansion Project

Raising a dam by adding concrete to it sounds simple. But it’s not.

Raising Gross Dam in Boulder County involves dozens of workers on site every day doing many different tasks. And the concrete? It’s used in different ways at various stages of the project.

During summer 2023, the future look of the renovated Gross Dam started to take shape as workers focused on shoring up the sides of the dam with — you guessed it — new concrete.

Learn more about the Gross Reservoir Expansion Project at grossreservoir.org.

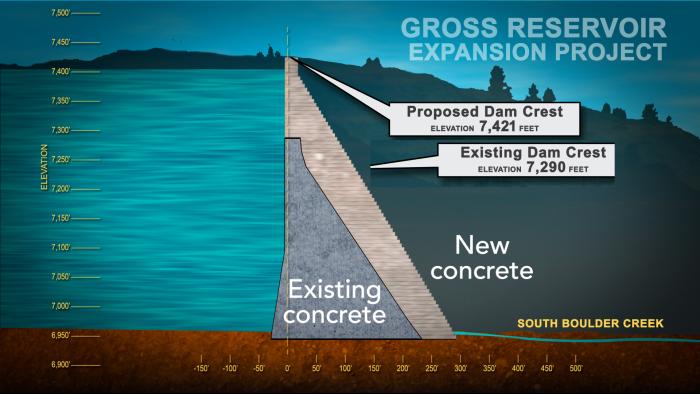

The Gross Reservoir Expansion Project, scheduled for completion in 2027, will raise the height of the existing dam by 131 feet to nearly triple the storage capacity of the reservoir. The additional water stored in the expanded reservoir will add balance and resiliency to Denver Water’s collection system, which serves 1.5 million people in the Denver metro area.

Increasing the height of the dam today is just as challenging as building the original dam back in the 1950s, according to Doug Raitt, the project’s construction manager for Denver Water.

“It’s a very complex process with multiple steps required before we can move to the next phase of actually building the new dam,” Raitt said. “We’ve got lots of people and equipment and we had some challenging working conditions (at the site) with all the lightning, rain and mud this past spring.”

Concrete solutions

Once the expansion project is completed, Gross will be the tallest dam in Colorado. However, before any work is done to raise the height of the dam, workers have to prepare the foundation to make it longer and wider.

The current dam is 340 feet high, 1,050 feet long across the crest and 267 feet wide at the base.

The new dam will be 131 feet higher (a total of 471 feet high) and almost twice as long (2,040 feet) across the crest. It will also be up to 90 feet thicker than the existing dam.

The project started in April 2022, and workers have already spent roughly 15 months excavating rock on the hillsides above the dam to clear the way for the dam’s bigger footprint. Raitt said there are still several months of excavation left before crews are finished with that phase of the project.

Once the rock was removed, workers were left with two trenches of jagged granite that must be smoothed and strengthened into a foundation sturdy enough to support the new layers of concrete that will be added as the dam is raised. The actual raising of the dam is scheduled to begin in 2024.

Join people with a passion for water at denverwater.org/Careers.

“When we remove the rock, we can’t just start building on top of it, instead we have to prepare the site,” Raitt said. “This process involves using different types of concrete and grout that serve various functions to make sure we have a secure foundation when we build up.”

The three steps to prepare the foundation include placing two types of concrete, called “dental” and “foundation” concrete, and injecting grout into the rock.

Dental concrete is the term for a type of concrete that is used to fill in the small nooks and crannies in the excavated areas to smooth them out. It gets its name from its similarity to filling in cavities from tooth decay.

Foundation concrete is a thicker mix used to cover the areas where the rock requires additional reinforcement to support the weight of the future, higher dam, or where the rock will not bond properly with the new dam concrete that will be used to construct the new addition.

Once the dental and foundation concrete has been placed on the surface, crews take the additional step of injecting grout into the rock. The grout fills tiny gaps in the rock in order to strengthen it to support the new, larger dam.

The foundation work will continue through 2023. In 2024, workers will start building the new concrete steps that will form the new dam.

The raised dam will have a type of concrete called “roller compacted concrete.” (Stay tuned for more on that in future TAP articles and videos.)

“The project is going very well, we’re hitting our objectives for the foundation work,” Raitt said. “The foundation work is critical to provide uniform support and take care of any imperfections in the rock.”