Practice makes perfect when putting concrete in place

In a remote part of Boulder County, a large, multilayered slab of concrete rises from the dirt. But it’s not the base of any new building, bridge or road.

The slab is a test bed for crews building what will be the highest dam in Colorado.

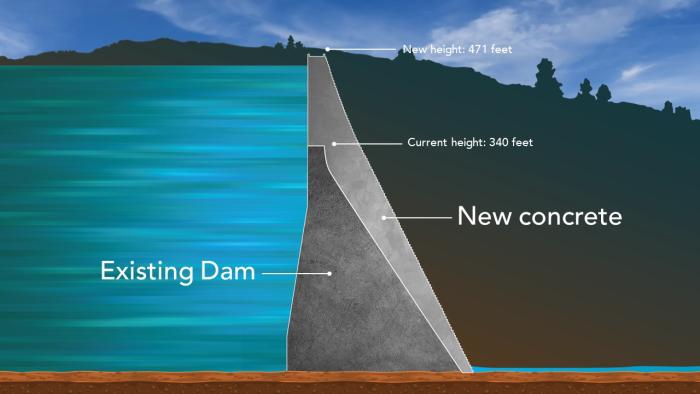

Denver Water’s Gross Reservoir Expansion Project will raise the height of Gross Dam by 131 feet, nearly tripling the water storage capacity of the reservoir behind the dam.

Engineers plan to raise Gross Dam by building about 118 concrete steps bonded to the front of the existing dam. Each step will be 4 feet tall, with a 2-foot setback from the one below it.

Construction of the steps will start at the bottom and rise to the dam’s new height of 471 feet. The construction also will make the top crest of the dam itself roughly twice as long and up to 90 feet thicker than the original dam that was built in the 1950s.

The steps will be made out of roller-compacted concrete, or RCC. It’s a type of concrete that takes its name from the way it is applied in the construction process: Workers will put the concrete in place, roll it onto the surface of the step and then compact it into place.

“Using roller-compacted concrete is the modern and most efficient means of building a concrete dam,” said Doug Raitt, construction project manager at Denver Water.

“RCC uses the same ingredients as other forms of concrete, but it uses less mixing water, so it’s stiffer and can be placed quickly on a site.”

Check out the different types of jobs and careers involved in delivering water to 1.5 million people at denverwater.org/Careers.

Conventional concrete, which is commonly used to make sidewalks or buildings, has more liquid and requires a longer time to initially set.

By comparison, the roller-compacted concrete that will be used at Gross Dam is firm enough that machines can immediately drive on the fresh concrete, rolling and compacting it into place, much like road base.

Roller-compacted concrete has a lower cement content than other kinds of concrete, allowing for a shorter time period for the initial set and a longer curing period for the concrete to reach its final design strength, Raitt said.

Raitt said the test slab allows the expansion project design team to figure out the best way to tackle various aspects of raising the dam, including:

- Producing and delivering roller-compacted concrete on-site.

- Training workers to place the concrete with various machines and work in confined spaces.

- Testing the concrete mixes and validating early laboratory tests about the performance of materials used in the production of the concrete.

A bulldozer spreads the roller-compacted concrete across the test slab. Photo credit: Denver Water.

Construction of the test slab served as a real-life example of the process crews will follow to build each step in the addition to the dam.

Construction of a step goes like this:

- Crews install formwork, the temporary walls used to hold fresh concrete in place until it cures and sets, following the design for each step of the dam addition.

- A special dump truck loaded with concrete drives up on tank-like tracks, spins around and dumps the concrete onto a desired location.

- Then, a bulldozer spreads the concrete across the surface in uniform layers that are 1-foot thick.

- Next up, a machine with a smooth-drum roller drives over the surface of the fresh concrete, compacting it and flattening the surface.

- Another machine then pushes down on the concrete to even out the surface and compact hard to reach corners of the material.

The process is repeated over and over until the concrete “step” reaches 4 feet in height. Once the concrete hardens, the process continues to build the next step.

“It’s exciting to see this process in action and how we’ll build the new part of the dam,” Raitt said.

“We didn’t want to try this on the dam itself until we had tested everything. We’re learning a lot from this trial placement so our crews will be ready for the real thing next season.”

Listen to Doug Raitt, Denver Water construction manager, explain how the roller-compacted concrete cures and sets:

Engineers will make saw cuts and drill into the slab to examine core samples over the coming months to assess the strength of the concrete. Over the winter, the design team will continue to refine the construction process.

Work to build the actual steps that will make up the new addition to the dam is expected to begin in the spring of 2024. It will take roughly 740,000 cubic yards of roller-compacted concrete to build the 118 steps.

Engineers also plan to use 68,000 cubic yards of conventional concrete on the exterior face of the dam. This type of concrete holds up better against the extreme weather conditions the dam will see in the mountain canyon.

Construction of the new steps of the dam addition is expected to last through 2025. In 2026, workers will complete the top of the dam, which will include a control building, electronics, concrete railing and a bridge over the spillway.

Construction work on the project is scheduled to wrap up in 2027.

Visit grossreservoir.org for construction updates and to sign up for the project updates newsletter.