IT, more exciting than comics?

Editor's note: Ellen Olson is part of Denver Water’s Youth Education Team and worked with Denver Water experts attending Jeffcon 2024 to prepare activities that would align with students' studies and curriculum.

Hearing of a high school student spending a day off at Comicon isn’t surprising, but skipping a day to learn about IT? That might raise an eyebrow.

Since 2017, hundreds of students in Jefferson County have chosen to spend a day off at Jeffcon, the school district's annual student tech conference, learning about jobs and careers involving information technology from the adults who work in IT every day.

At Denver Water, interest in IT is no surprise. We know about the cool and amazing opportunities that are part of this industry. We’re also aware that the breadth of opportunities in this industry aren’t very well advertised.

So, for the last two years, a team of our own technology experts has headed to this immersive technology experience to share with students the integral role technology plays at a drinking water utility.

“We actually had our folks fighting over who gets to go this year,” said Mark Thomas, Denver Water’s IT director.

Members of Denver Water’s IT industrial controls group helped about 20 students build programmable logic controllers, or PLCs, the small, rugged industrial computers programmed to control processes such as those found on assembly lines and in machines and robotic devices.

The technical names used in the industry might perpetuate the notion that IT is boring, but the work is not. Are you familiar with a Ring doorbell? Essentially, students worked with equipment and processes similar to the ubiquitous doorbell.

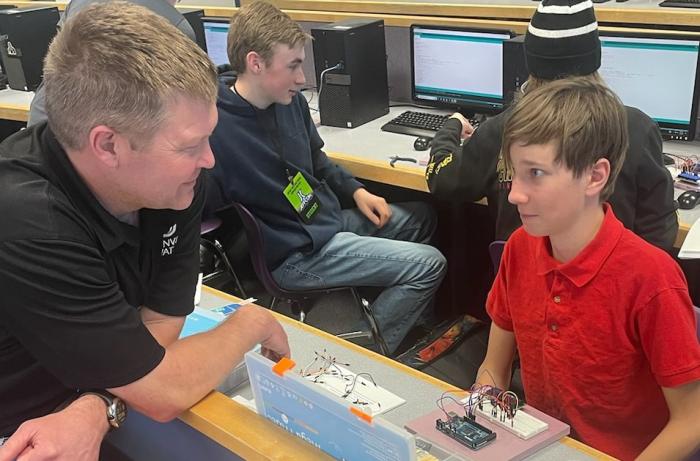

Using microcontrollers and breadboards, students wired connections and programmed the units to explore the capabilities of logic controllers.

Students worked to wire and program electronic displays, radio-frequency identification readers and warning sounds. It didn’t take long. These students are quick, and their eyes lit up with enthusiasm as the classroom filled with witty sayings on the electronic displays and the din of warning bells.

“Being here is part of giving back to our community. This is also our way of fulfilling the Denver Water vision to sustain vibrant communities by showing young people the options available to them with a career in water,” said Drake Dennert, who leads Denver Water’s industrial controls team.

As students worked through their assignment, the industrial controls team walked through the classroom, providing a tip here and there or congratulating a student on their work.

At Denver Water, this team doesn’t just sit behind a computer. They work at treatment plants and across the 335-square-mile service area implementing programs that feed treatment processes, monitor the quality of the water and alert operators when needed.

For example, the industrial controls team is responsible for roughly 300 pH probes that constantly monitor the water flowing throughout Denver Water’s distribution system. This is a critical component of Denver Water’s Lead Reduction Program and to ensure water quality for 1.5 million people across the metro area.

Go behind the scenes with this team in an innovative, yearlong study of 11 models of pH sensor probes used by the water industry to find the best pH probes to protect Denver Water customers from lead.

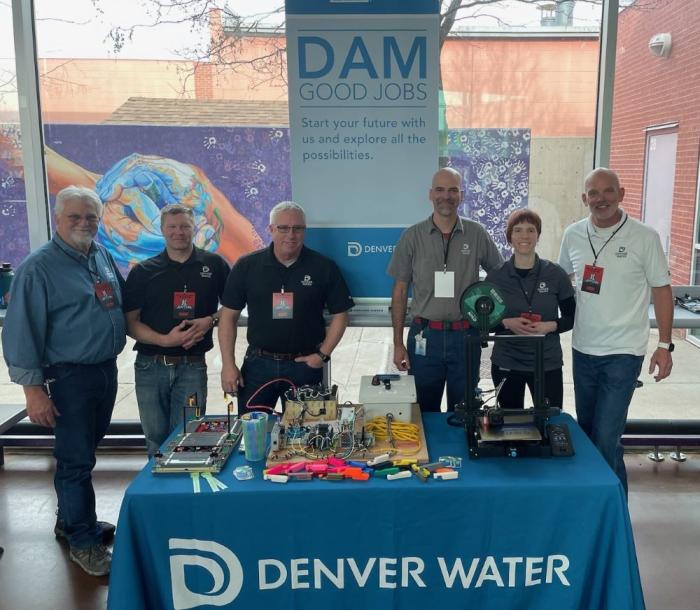

Dennert, along with Alvin Johnson, Ken Heaps, Dominique Ingoglia and Joe Burcham, facilitated two, 95-minute learning sessions during the conference.

“We provided a peek into the capabilities of (programmable logic controllers) and the world of industrial controls,” said Johnson, IT industrial control tech supervisor. “They now have the tools to explore more and let their imagination run with the possibilities.”

“Who knows? Maybe one of these students is a future Denver Water employee,” added Dennert.