Reference Denver Water Engineering Standard Details: 33260, 33262, 33271

- Tapping valve installed on water main.

- Service line is perpendicular to the curb-line.

- Stop box and meter vault are in landscaped area, and match finished grade.

- Permanent obstructions are 5 feet clear of the meter vault:

- Utilities, street lights, foundations, fence lines, retaining walls, backflow prevention devices.

- Plantings, shrubs and branches must remain 5 feet clear of the meter pit/vault lid.

- Trees must be 10’ away from meter vault.

- Permanent obstructions are 5 feet clear of the meter vault:

- Service line has no bends or connections until 5 feet downstream of the meter vault.

- Manhole cover is offset over the access ladder.

- Manhole cover meets Denver Water Engineering Standards:

- Single automated meter reading recess (turbine meters).

- Dual automated meter reading recesses (compound meters).

- Manhole must be located above meter

- If manhole will be in concrete it must be a smooth lid.

- Manhole cover meets Denver Water Engineering Standards:

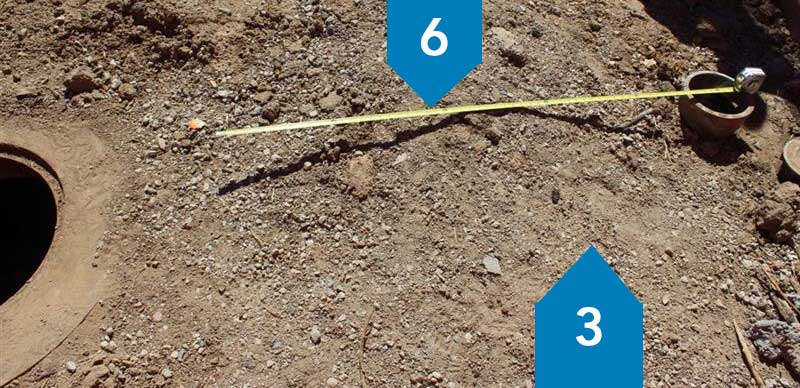

- Stop box is 2 to 5 feet from outside wall of meter vault.

- Service line depth is between 54 and 72 inches.

- Stop box is plumb and centered over the curb valve.

- Manhole concrete riser collar(s) plus manhole ring do not exceed 18 inches.

- Extra ladder rung may be required denending on distance to first rung.

- Meter vault is the appropriate size:

- 8 feet x 9 feet (3 inch, 4 inch, and 6 inch services).

- 8 feet x 13.5 feet (8 inch and larger services).

- Restraints are installed across bolted sleeve type couplings.

- Restraints are attached with dog eared flanges.

- If ductile iron is not epoxy coated, it must be wrapped with wax tape and covered with poly film. This shall also include the coupling and the rodding. Do not wrap valves or meter. If pipe is epoxy coated, wax tape and rodding must still be wrapped.

- Penetrations around piping must be grouted with non-shrink grout.

- Gate valves have wheel operators installed.

- Gate valves are supported by steel pipe supports (Denver Water Engineering Standard Detail 05001).

- Strainer (not pictured) is installed upstream of the meter (turbine meters only).

- Concrete support block and shims support the meter flanges. Steel pipe supports may be substituted for concrete block and shims. Install one under each meter flange.

- Bolted Sleeve Type Coupling.

- No bypass pipe on irrigation meters.

- If backflow is required it must be installed prior to meter inspection, including fire line backflow if applicable. Backflow device MUST match size of pipe that penetrates building.

Reference Denver Water Capital Projects Construction Standards: 22017